3 min read

How the Kraljic matrix improves your supplier management and procurement process

Christian Willemsen

14-Jul-2022 9:30:06

Despite the fact that indirect spend usually does not exceed 20% of corporate spending, the ordering frequency is usually much higher than for direct spend. The indirect purchasing process is often hardly organized. As a result, the (hidden) costs associated with sourcing and ordering products for secondary business activities are significant. To increase spend under management, tools and processes must be implemented and agreements made even before an order goes out the door. Supplier management is one of the key components of the Kraljic matrix can help with this.

Classifying suppliers using the Kraljic matrix

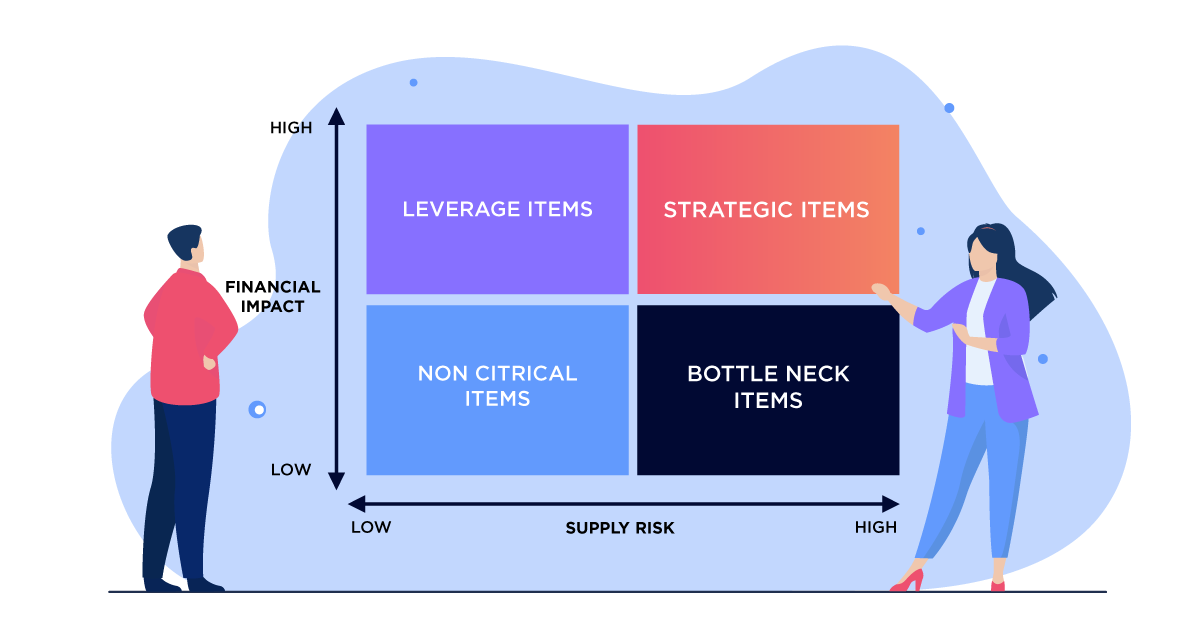

The Kraljic matrix helps Procurement qualify the products (and services) procured by the organization based on supply risk and impact on business results. This qualification determines how you design the procurement process and what kind of relationship you establish with suppliers.

Identifying these suppliers and determining how important these suppliers are to your organization will improve your supplier management and thus the procurement process. The Kraljic matrix consists of two axes: risk/complexity - particularly supply risk - and impact on profits. Looking at the category where the supplier/product belongs, you determine its impact on your profitability. Four categories are used to classify suppliers and the products they sell. These are:

- Non critical items: low risk, low impact on profits

- Leverage items: low risk, high impact on profits

- Bottleneck items: high risk, low impact on profits

- Strategic items: high risk, high impact on profits

Defining your relationship with suppliers

These four categories will help you define the relationship to be established with suppliers. In other words, is there only one supplier that can provide the product that is critical to your core business? Or is it one of many suppliers and can you buy this product elsewhere?

Suppose you have only one supplier who can make specific chips. If this supplier has supply problems, then everyone in the chain has problems. In the Kraljic matrix, this is a strategic item that carries supply risk and has a major impact on your profitability and core business if the product cannot be delivered.

To ensure business continuity, you can take several actions. You can improve or intensify your relationship with suppliers, for example, by seconding an employee to the supplier. You can even consider buying (a business unit of) a supplier, or in extreme cases, decide to make the strategic item yourself.

But if your organization has only one supplier who can supply a strategic item, it is also wise to start a sourcing process, for example, and start exploring the market. There may be more suppliers who can deliver (almost) the same product.

By working with multiple suppliers, you reduce risk, ensure greater spread and security of supply, and problems at one supplier have less impact on your organization. The Kraljic matrix provides this insight, both for direct procurement and indirect procurement.

Supplier management and selecting preferred suppliers

The Kraljic matrix also helps to improve supplier management by providing insight into how many suppliers you approach per category. With noncritical items such as office furniture, there are many suppliers and many different types of furniture, so the supply risk is low and so is the impact on your profitability. You can easily approach another supplier if your own supplier has problems.

📺KIJKTIP: Automating versus optimizing in Purchase to Pay

By putting your suppliers who supply office furniture into the Kraljic matrix, you will gain insight and you may see that there are a lot of suppliers in the supplier database who can supply about the same thing. These may be suppliers with whom ad hoc orders placed without a contract with your organization.

You can reduce the cost of the ordering process of non critical items by working with one or a select group of preferred suppliers, with whom you can enter into more advantageous contracts. In practice, it is not feasible to assess all suppliers in this way; it makes more sense to look at the 20% of suppliers that cover 80% of expenses.

Supplier reviews

To select the most important suppliers - and thus your preferred suppliers - you can look at your supplier ratings. Besides price, value for money and CSR aspects such as sustainability and handling of human rights are very important these days.

For example, you see that fifty suppliers can supply the product, only ten of them meet your conditions, and three of them score best in terms of sustainability. These three then become your preferred suppliers that you sign contracts with.

The other seven are Category B and C suppliers that do not meet all the requirements. If your three preferred suppliers have supply problems, you may decide to look at the seven other suppliers and contract with some of them.

Purchasing can thus develop a strategic plan for supplier management, resulting in a clear purchasing process. Everyone in the organization knows which product may be ordered from which supplier, and each order is recorded in a purchase order. The purchasing process thus becomes manageable and predictable, which can greatly reduce the costs of the ordering process.

Have you already identified, qualified and made a plan of action for all your suppliers? Feel free to contact me to exchange views on this.

|

Christian Willemsen |

PS Don't forget to subscribe to our blog updates!